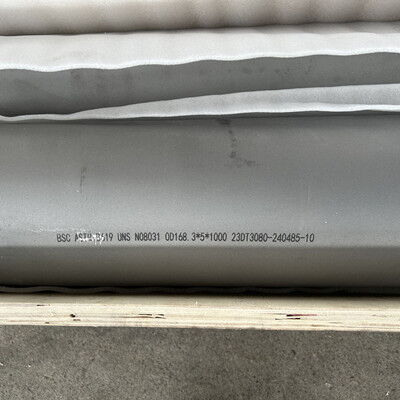

ASTM B619 UNS N08031 SEAMLESS PIPE

Key Specifications / Features

Model No.: DW-Ni-01 Hits: 6

Alloy 31 (N08031) nickel alloy is a nitrogen-containing iron nickel chromium molybdenum alloy with properties between super austenitic stainless steel and existing nickel based alloys. Alloy 31 (N08031) nickel alloy is suitable for application in industrial fields such as chemistry and petrochemicals, environmental engineering, and oil and gas production.

Request a quote

Share

Tags

Detail Information

ASTM B619 UNS N08031 SEAMLESS PIPE

N08031 (Alloy31) is a high alloy austenitic stainless steel with excellent corrosion resistance, widely used in fields such as chemical, petrochemical, marine engineering, and environmental technology. It is particularly suitable for resisting corrosion from sulfuric acid, hydrochloric acid, phosphoric acid, and chlorine containing environments. Its excellent resistance to pitting and crack corrosion, as well as high temperature stability, make it the preferred material for many high-end industrial applications.

Product features:

◾ Excellent corrosion resistance in alkaline and acidic halide media.

◾ Maintain good corrosion resistance to high concentrations of sulfuric acid.

◾ Excellent corrosion resistance and wear resistance in phosphoric acid medium.

◾ In the field of papermaking, chlorine dioxide bleach media equipment exhibits excellent resistance to uniform corrosion and localized corrosion.

◾ Excellent corrosion resistance is maintained in both reducing and oxidizing media, as well as in boiling peroxidized nitric acid.

◾ Good processability and weldability.

◾ Certified by VdT Ü V, suitable for pressure vessels operating at temperatures ranging from -196 to 550 ° C.

◾ Certified by ISO 15156/NACE MR 0175, it can be used for acidic gas applications below Class VI in the petroleum and natural gas industry.

◾ Certified by ASME, suitable for pressure vessels below 427 ° C (800 ° F).

Product Usage:

◾ Components of flue gas desulfurization device

◾ Wet process phosphoric acid production equipment

◾ Pipelines and heat exchangers for sulfuric acid contaminated with chlorides

◾ Seawater and saltwater pipelines, condenser and chiller unit pipelines

◾ Pickling equipment for sulfuric acid and hydrofluoric acid nitric acid

◾ Treatment of waste sulfuric acid

◾ Evaporation and crystallization of salt

◾ Pulp and paper industry equipment

◾ Decomposition of ores, such as filtration of laterite in HIPAL equipment

◾ Oil production and refining plants

◾ Synthesis of organic acids and esters

◾ fine chemicals

◾ Strain hardened transportation and supply pipelines in the field of oil and gas transportation

Supporting welding materials:

ErniCrMo-13 welding wire, ENiCrMo-13 welding rod

N08031 (Alloy31) is a high alloy austenitic stainless steel with excellent corrosion resistance, widely used in fields such as chemical, petrochemical, marine engineering, and environmental technology. It is particularly suitable for resisting corrosion from sulfuric acid, hydrochloric acid, phosphoric acid, and chlorine containing environments. Its excellent resistance to pitting and crack corrosion, as well as high temperature stability, make it the preferred material for many high-end industrial applications.

Product features:

◾ Excellent corrosion resistance in alkaline and acidic halide media.

◾ Maintain good corrosion resistance to high concentrations of sulfuric acid.

◾ Excellent corrosion resistance and wear resistance in phosphoric acid medium.

◾ In the field of papermaking, chlorine dioxide bleach media equipment exhibits excellent resistance to uniform corrosion and localized corrosion.

◾ Excellent corrosion resistance is maintained in both reducing and oxidizing media, as well as in boiling peroxidized nitric acid.

◾ Good processability and weldability.

◾ Certified by VdT Ü V, suitable for pressure vessels operating at temperatures ranging from -196 to 550 ° C.

◾ Certified by ISO 15156/NACE MR 0175, it can be used for acidic gas applications below Class VI in the petroleum and natural gas industry.

◾ Certified by ASME, suitable for pressure vessels below 427 ° C (800 ° F).

Product Usage:

◾ Components of flue gas desulfurization device

◾ Wet process phosphoric acid production equipment

◾ Pipelines and heat exchangers for sulfuric acid contaminated with chlorides

◾ Seawater and saltwater pipelines, condenser and chiller unit pipelines

◾ Pickling equipment for sulfuric acid and hydrofluoric acid nitric acid

◾ Treatment of waste sulfuric acid

◾ Evaporation and crystallization of salt

◾ Pulp and paper industry equipment

◾ Decomposition of ores, such as filtration of laterite in HIPAL equipment

◾ Oil production and refining plants

◾ Synthesis of organic acids and esters

◾ fine chemicals

◾ Strain hardened transportation and supply pipelines in the field of oil and gas transportation

Supporting welding materials:

ErniCrMo-13 welding wire, ENiCrMo-13 welding rod

Comment Form