Quality Control

Quality Control

Duwa Piping have set up a complete quality control system to make sure the perfect operation of every workflow during production process. Every detail of the products and production process strictly conforms to the ISO 9001:2008.

Before making a work plan and carrying it out, we identify the requirements of customers firstly. Assess and measures will be made to ensure the max use rate of capital and materials. Statistics of them will be gathered for better monitor so that you won’t have to worry about the size and spend.

We also have superior equipment and machines to push the fulfillment of perfect work. We keep long-term relationship with many well-known raw material suppliers which lead to more competitive quote of our products. All staff in our company are seasoned and responsible. Thanks to them, our company and products are becoming better and better.

We accept any Third Party of Inspection appointed by our customers, such as Lloyd's Register, TUV, DNV, BV, SGS, IEI, SAI etc. All goods will be inspected before package and dispatching.

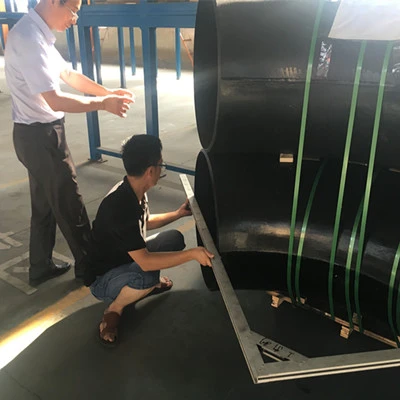

Below is a few examples of our quality control inspection before delivery:

Elbow Degree Inspection

Elbow Radius Thickness Inspection

Flange Chemical Composition Test

Valves Hydraulic Test

Before making a work plan and carrying it out, we identify the requirements of customers firstly. Assess and measures will be made to ensure the max use rate of capital and materials. Statistics of them will be gathered for better monitor so that you won’t have to worry about the size and spend.

We also have superior equipment and machines to push the fulfillment of perfect work. We keep long-term relationship with many well-known raw material suppliers which lead to more competitive quote of our products. All staff in our company are seasoned and responsible. Thanks to them, our company and products are becoming better and better.

We accept any Third Party of Inspection appointed by our customers, such as Lloyd's Register, TUV, DNV, BV, SGS, IEI, SAI etc. All goods will be inspected before package and dispatching.

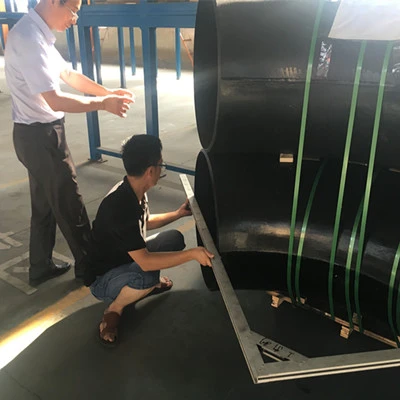

Below is a few examples of our quality control inspection before delivery:

Elbow Degree Inspection

Elbow Radius Thickness Inspection

Flange Chemical Composition Test

Valves Hydraulic Test